MIL-DTL-16884N

APPENDIX A

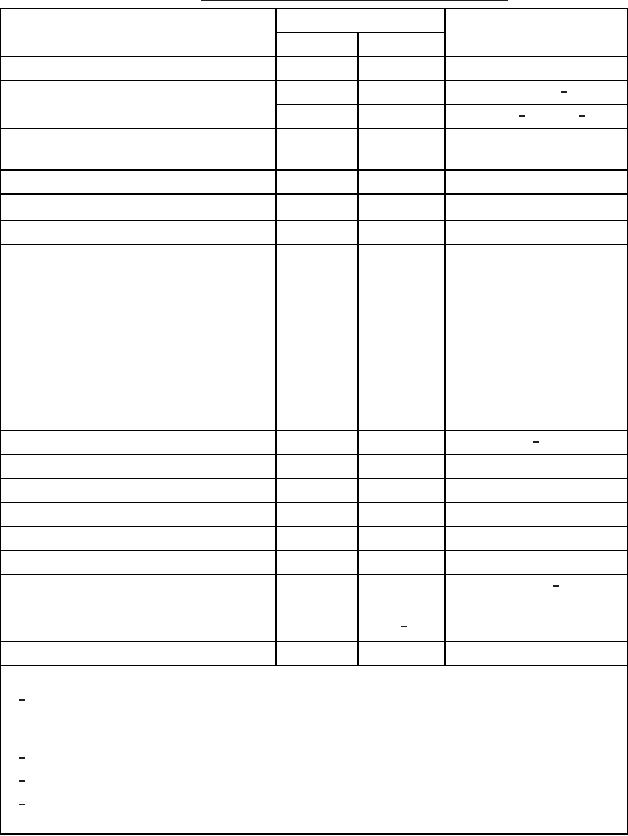

TABLE A-I. Detailed batch requirements; hydroprocessed SPD.

Requirement

Characteristic

ASTM Method

Minimum

Maximum

Acid Number, mg KOH/g

0.08

D974 (R), D664

D524 (R) 1/

Carbon Residue on 10% bottoms, mass %

0.20

D189 1/, D4530 1/

0.14

Cloud Point, °C

-1

D2500 (R), D5771,

D5772, D5773

Corrosion, 3 hours at 100 °C

No. 1

D130

Density, at 15 °C, kg/m3

770

805

D1298 (R), D4052, D287

Derived Cetane Number

42

80

D6890, D7170

D86

Distillation:

Report

Initial Boiling Point, °C

290

191

10% Recovered, °C

Report

50% Recovered, °C

357

290

90% Recovered, °C

385

300

Final Boiling Point, °C

Report

T50-T10, °C

20

T90-T10, °C

3.0

Residue + Loss, volume %

D93 (R) 2/, D3828

Flash Point, °C

60.0

Heating Value, MJ/kg

43.5

D4809

Hydrogen Content, mass %

14.5

D7171 (R), D4808, D5291

Kinematic Viscosity, at 40 °C, mm2/s

1.7

4.3

D445

DSEP

85

D7261

Particulate Contamination, mg/L

1.0

D6217 (R), D5452

D3241 3/

Thermal Stability:

25

Change in Pressure Drop, mm of Hg

3 4/

Tube Deposit Code, less than

Total Water, mg/kg

100

D6304

NOTES:

1/

Fuel must meet the requirements for one of the three test methods. If ASTM D189 or ASTM

D4530 is performed in lieu of the referee test method, ASTM D524, the maximum allowable

carbon residue shall be 0.14 mass percent.

2/

ASTM D3828 may give results up to 1.7 °C below the ASTM D93 results.

3/

4/

If the visual rating of the heater tube shows Peacock (P) or Abnormal (A) type deposits, the

fuel sample is not acceptable.

15

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business