MIL-DTL-46162E

3.2.1.2.3 Static dissipator additive. An additive shall be added to the fuels in sufficient

concentration to increase the conductivity of the fuel to within the range specified in table II at

the point of injection. The point of injection of the additive shall be determined by agreement

between the purchasing authority and the supplier. The following electrical conductivity

additive Stadis 450 is an approved additive (see 6.6.3).

3.2.1.2.4 Corrosion inhibitor. A corrosion inhibitor conforming to MIL-PRF-25017

(see 6.6.5) shall be blended into the fuel by the contractor. The amount added shall be equal to

or greater than the minimum effective concentration and shall not exceed the maximum

allowable concentration approved by manufacturer. The contractor or transporting agency, or

both, shall maintain and upon request shall make available to the Government evidence that the

corrosion inhibitors used are equal in every respect conforming to MIL PRF-25017. The point of

injection of the corrosion inhibitor shall be determined by agreement between the purchasing

authority and the supplier.

3.2.1.2.5 Fuel systems icing inhibitor. An icing inhibitor conforming to MIL-DTL-85470 is

mandatory and shall be blended into the fuel system.

3.3 Physical and chemical requirements. The finished referee fuels shall conform to the

requirements specified.

a. Types I and II fuels are not intended for use where ambient temperatures lower then -

30°C (-22°F) generally occur.

b. When authorized NATO F-34 (JP-8) may be used in ground based turbine and diesel

engines.

3.3.1 Type I referee fuel. The finished type I referee fuel which meets the minimum

requirements of A-A-52557 shall conform to the requirements specified in table I.

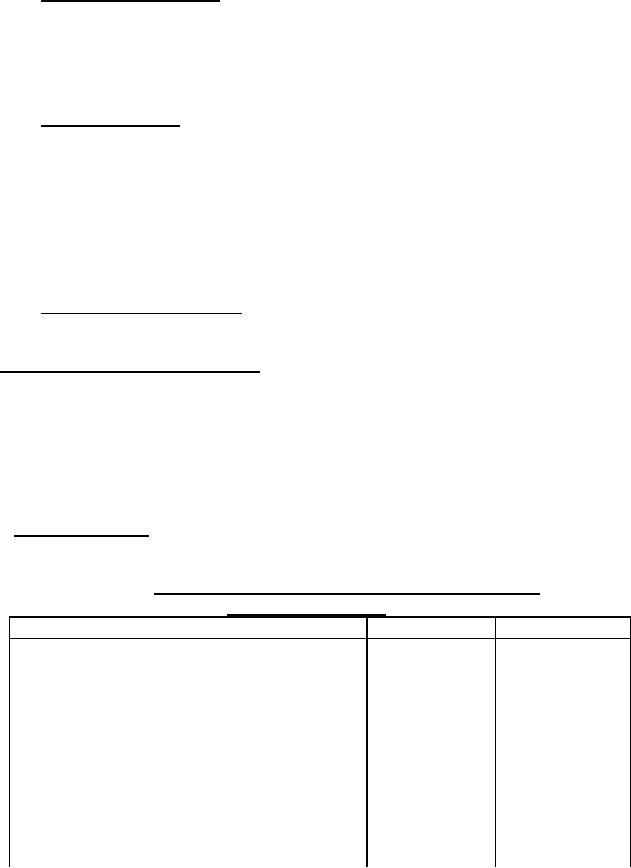

TABLE I. Physical and chemical requirements and test methods

for type I referee fuel.

Property

Value

ASTM

Density, Kg/L @ 15°C

Record

D1298

Flash point, °C, min.

52

D93

Cloud point, °C, max.

-13

D2500

Pour point, °C, max.

-18

D97

Kinematic viscosity, cSt at 40°C

1.9 to 4.1

D445

Distillation, °C

D86

Initial boiling point

Record

10% recovered, min.

220

50% recovered

255 to 305

90% recovered

310 to 360

95% recovered

315 to 365

8

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business