MIL-DTL-46162E

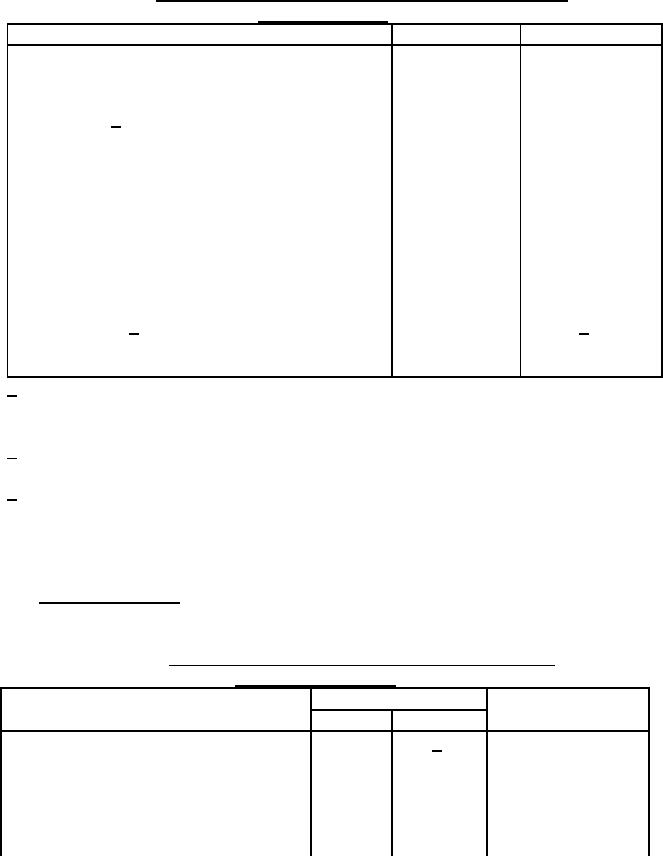

TABLE I. Physical and chemical requirements and test methods for

type I referee fuel Continued.

Property

Value

ASTM

End point, max.

385

Residue volume %, max.

3

Carbon residue on 10% bottoms, % wt, max.

0.20

D524

Sulfur, % wt 1/

0.95 to 1.05

D1552, D129,

or D2622

Copper strip corrosion, 3 hours @ 50°C, max.

1

D130

Ash, % wt, max.

0.02

D482

Accelerated stability, total insolubles,

1.5

D2274

mg/100 mL, max.

Neutralization No., TAN, max.

0.2

D974

Aromatics, volume %

Record

D1319

Net heat of combustion, MJ/kg

Record

D240

Particulate contamination, mg/L, max.

10

D6217

Cetane number 2/

37 to 43

D613 3/, D976,

or D4737

Free water & particulate contamination

Pass

D4176

1/ Naturally-occurring sulfur is preferred. If additional sulfur is required, supplementation

shall only be achieved by blending sufficient amounts of ditertiary butyl disulfide to the

finished fuel.

2/ See appendix A. If the fuel contains cetane improver additives, this limit shall apply

only to the base fuel prior to addition of cetane improver.

3/ ASTM D613 is the referee method for determining cetane quality. ASTM D976 and

ASTM D4737 are permitted as alternates. If cetane improvers (as determined by the

method in appendix A) or non-naturally-occurring sulfur compounds have been

utilized, only ASTM D613 shall be permitted.

3.3.2 Type II referee fuel. The finished type II referee fuel which meets the min

requirements of MIL-DTL-83133, shall conform to the requirements specified in table II.

TABLE II. Physical and chemical requirements and test methods

for type II referee fuel.

ASTM Test

Requirements

Methods

Property

Min

Max

Color, saybolt

1/

D156

Total acid number, mg KOH/gm

0.015

D3242

Aromatics, vol percent

25.0

D1319

Olefins, vol percent

5.0

D1319

Sulfur, total, wt. percent

0.30

D1266, D2622

D3120, D4294

9

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business